- Home

- Solutions

- News and Events

- Hilti Blog

- Automation helps tackle industry challenges

Automation helps tackle industry challenges

The robots are coming! Actually, they’re already here – albeit in their less sensational forms of digitisation and automation. How can they help tackle the construction industry's biggest challenges? Read on to find out...

The benefits of using robots

Automated and semi-automated machines are most useful when carrying out mundane, repetitive or dangerous tasks that require accuracy or speed that exceed reasonable human limitations. Using robots to dig, drill, cut, weld, move heavy loads and pour concrete can help make jobsites more efficient, precise and safer. For example, robots...

- Allow humans to reallocate their time to more satisfying, high-value tasks

- Perform strenuous or dangerous tasks that would otherwise threaten the health and safety of humans

- Perform tasks in harsh conditions unsafe for humans

- Reduce insurance costs by mitigating human risk

- Work overnight to slash timelines

- Help avoid rework due to human error

of construction industry professionals

in the UK use Building Information Modelling (BIM) , according to a report in 2020 [1]

of UK contractors

experienced labour shortages during the last quarter of 2021 [2]

per hour in 2020

compared to 100 output per hour in 1970, proving construction productivity has grown very little in 50 years [3]

spent by UK construction companies

in 2020 to plug the short-term gaps resulting from skills shortages [4]

Though the construction industry is typically slow to adopt new technologies, automated and semi-automated robots are already in use around the world.

Examples include:

- Boston Dynamics Spot, a mobile robot that easily navigates jobsite terrain to perform inspection tasks and collect data

- Dusty Robotics FieldPrinter, which uses BIM data to print full-size floorplans straight onto the building deck

- Canvas, an automated drywall finishing machine

- Hilti Jaibot, a semi-automated cordless drilling machine for MEP and interior finishing installation work (especially overhead tasks) that can work for 8 hours on a single battery charge

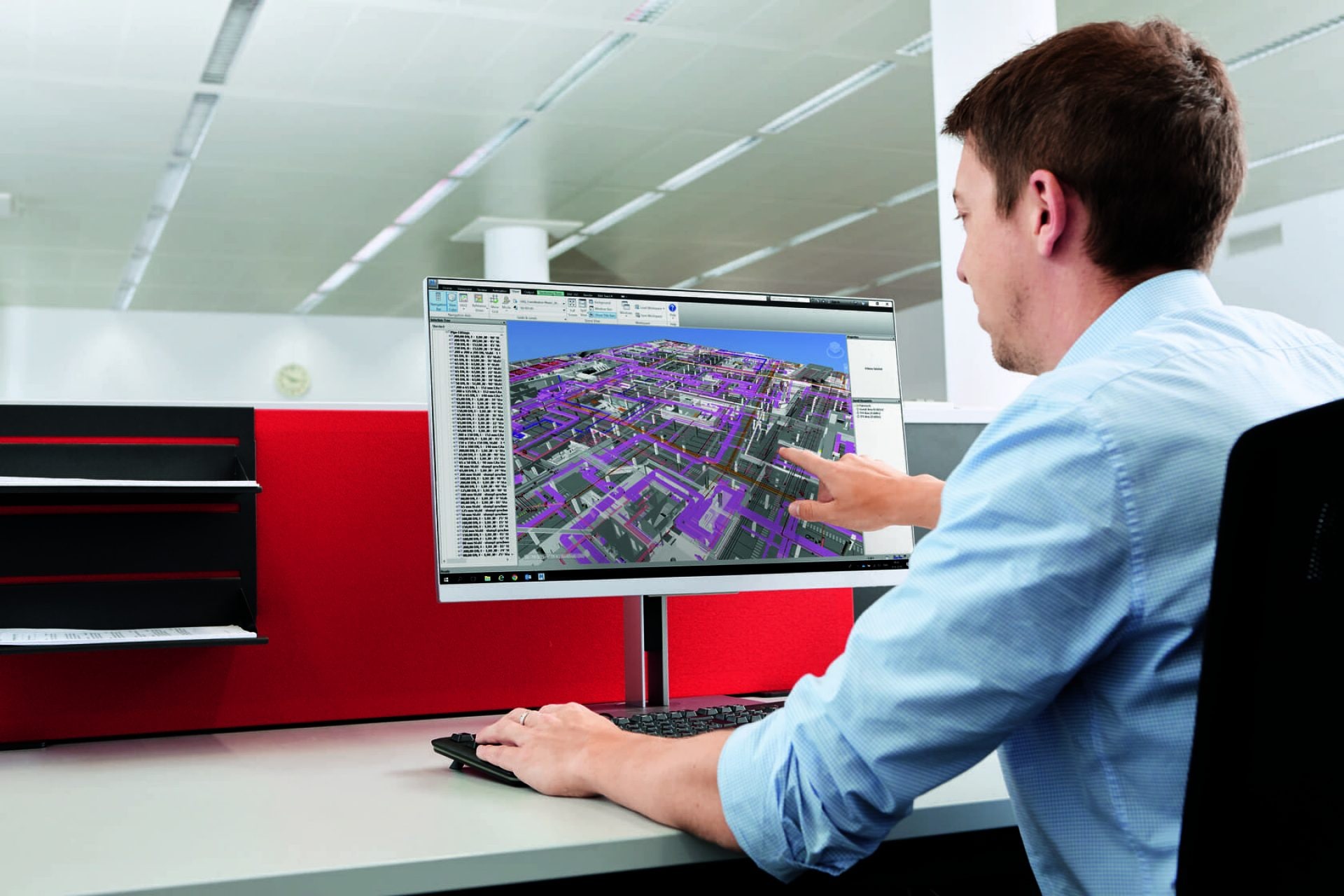

Boosting productivity through automation

It's no secret that the construction industry struggles to operate at peak productivity. In fact, there's barely been any growth in productivity over the past 20 years - largely due to the industry's fixed ways of working and unwillingness to change. But this unwillingness to change is negatively impacting not only productivity, but also profit margins.

Take mechanical, electrical and plumbing installations, for example:

- Mistakes in planning and execution can lead to inefficient on-site improvisations and costly reworks

- Coordinating multiple players with overlapping applications can be complex and expensive

- Repetitive work can be time-consuming, error-prone and demoralising

- Overhead work can be inefficient and physically demanding

- Skilled labour shortages can result in poor-quality installations that need to be redone

But even a slight bump in productivity can translate to a significant amount of money, especially on large and major projects. So, if increasing productivity is key to long-term success, where do you start? You start by evaluating your workflows end-to-end, identifying their inefficiencies and finding ways to optimise and then automate the processes.

The automotive and agriculture industries have already demonstrated that automation and digitisation can significantly boost productivity. A similar transformation can benefit the construction industry too. After all, it’s a relatively systematic and controlled industry - meaning it’s well positioned to take advantage of automation and digitisation.

How will this effect the human workforce?

There are always caveats - some fear that automation will take jobs away from humans. But the industry is already facing a labour shortage and employment demand continues to grow. Automation could help ease that number, especially with low-skilled jobs that are hard to fill.

The key is to combine human and robot talents, a concept known as collaborative robotics. For example, a robot still requires a human to manage its resources and programme its tasks, even with BIM helping to streamline the process. Collaborative robotics can help extend the productivity of older workers who have huge experience but are struggling with the more physical aspects of construction. It can also help contractors – especially those competing for high-quality talent – attract digital-native candidates that otherwise wouldn’t consider working in construction.

And as it stands, humans are still best suited to work that requires delicate handling and improvised decision-making. Leave the tedious jobs that demand extraordinary speed, strength and accuracy to the robots.

Time to walk the walk

Acquiring a robot often means making a significant investment in both up-front costs and time learning how to use and incorporate it into existing processes. When profit margins are low, spending hard-earned revenue on innovation seems risky. And when deadlines loom, no one wants to interrupt inefficient but functioning workflows – even if the long-term benefits far outweigh a short-term need to "just get it done."

However, not embracing technologies that can boost productivity is, well, not productive. Companies need to anticipate digital disruption and get ahead of it before their competitors do. Developing a digital strategy can begin with a simple ROI assessment – any contractor able to analyse project data and predict costs can determine if a new tech solution has value.

But companies also need to be bold, which means developing budgets and establishing KPIs that enable their project managers to try new technologies - like robotics - without fear of failure. Those that find ways to identify long-term productivity gains through automation will be far better positioned in the future.

To learn more about how construction robots and automation can help your business, fill out the form below and a member of our team will call you to discuss next steps!

Alternatively, you can register with us online and sign up to receive our newsletter - which contains exclusive updates on our latest technology and innovations.

(Already have an online account with us? You can manage your newsletter preferences here)