- Home

- Solutions

- Solutions

- Construction Safety

- Vibration

Minimise exposure to hand arm vibration

Active Vibration Reduction (AVR) technology and other practical strategies to help reduce vibration

In the construction industry, workers are unavoidably exposed to some vibration when they drill, chisel, break or grind materials. However, you can calculate, manage and minimise exposure to power tool vibration, to help keep construction workers safer, more comfortable and more productive.

As a responsible employer, you naturally want to increase the productivity of your team. So how can you manage the vibration intensity and duration team members are exposed to, while keeping work schedules on time? The Hilti tool selector has all the detailed information you need to manage HAVS exposure while getting the most out of your team's time on the tools.

How do you measure power tool vibration on your construction sites?

In Europe it's essential for employers to measure and monitor the vibration employees are exposed to in the workplace.

As such, employers following European Union-wide Exposure Action Values (EAVs) may need to act when exposure to vibration for an employee reaches 2.5 m/s2 over an average 8-hour period[1].

In addition, the EU sets out Exposure Limit Values (ELVs), for the maximum amount of vibration an individual can be exposed to on a single day being 5 m/s2 over an average 8-hour period.

In Great Britain, the Health and Safety Executive (HSE) publishes a hand-arm vibration exposure calculator [2] to help employers measure and monitor vibration. However, it’s important to realise that a higher m/s2 doesn’t necessarily mean a higher risk. To choose the right tool for the job, you need to consider other factors such as tool performance, corresponding fatigue, and “trigger time” (time spent using vibrating tools).

For these reasons, we recommend you also use the Hilti tool selector – which calculates how much work you can do before reaching limit and action values – helping you to choose the right tools for the job and reduce exposure time. The selector also gives you information to calculate dust and noise values, which also help to manage health and safety onsite.

So how can you minimse construction vibration, increasing productivity and leading to healthier jobsites? We recommend following the "STOP Principle" of Substitution, Technical, Organisational and Personal Protective Equipment (PPE).

Why having the correct tools is the key to improving construction site productivity

Low vibration value doesn't always mean it's the safest tool for the job

It seems obvious to think that the tool with the lowest vibration value would be the safest tool for job however that's not always the case. Especially when you factor in the power of the tool and consider how quickly it could get the job done.

Consider this example...

Imagine you were breaking out 0.5 cubic meters of concrete from a wall, with a depth of 25 cm and you had the choice to use either the TE 700-AVR or TE 800-AVR breaker.

The TE 700-AVR breaker has a vibration value of just 6.5 m/s2 while the TE 800-AVR has a higher vibration value of 8 m/s2 .

So far, it looks like an easy choice. However, when tool performance is factored in, the TE 800-AVR finishes the application 50% quicker than the TE 700-AVR, meaning the worker is exposed to 27% less vibration than they would if they had used the tool with the lower vibration value.

The other significant benefit is that the worker would finish the job in more than half the time than if they used the TE 700-AVR bringing huge productivity gains, as well as improved working comfort and health and safety.

Substitution: Eliminate the risks of vibration by using alternatives

By substituting traditional methods with alternatives designed to minimise, and in some cases even eliminate hand-arm vibration exposure, the root cause of hazards can be avoided.

Alternative methods to reduce the impact of harmful vibration onsite include:

Drilling

Choose low-vibration diamond coring tools, such as the DD 30-W, instead of combihammers. Reduce vibration exposure further by using a rig-mounted system. Wet coring systems also offer effective dust suppression, minimising exposure to hazardous silica dust in the process.

DD 30-W diamond coring tool

Breaking

Use rig-mounted diamond wall saws and coring tools, such as the DD 350-CA, instead of hand-held combihammers and breakers for virtually dust-free drilling and minimal HAVS exposure. Working with a Cut Assist automatic feed unit makes it a highly efficient and fully automated process.

DD 350-CA diamond coring tool

Cutting

When cutting wood handheld, consider circular saws that have lower vibration values than reciprocating saws.

Cordless circular saws

Direct fastening

Switch to low-vibration, virtually dust-free direct fastening – such as the BX 3 battery-powered nailer – instead of drilling to fasten anchors, screws and studs which expose workers to both HAVS and silica if dust removal systems aren't in place.

BX 3 battery-powered nailer

Designing out construction vibration

Place our HAC cast-in anchor channels around the rebar before the concrete is poured, meaning little or no drilling and therefore no dust or vibration.

HAC cast-in anchor channels

Technical: System solutions to reduce vibration from power tools

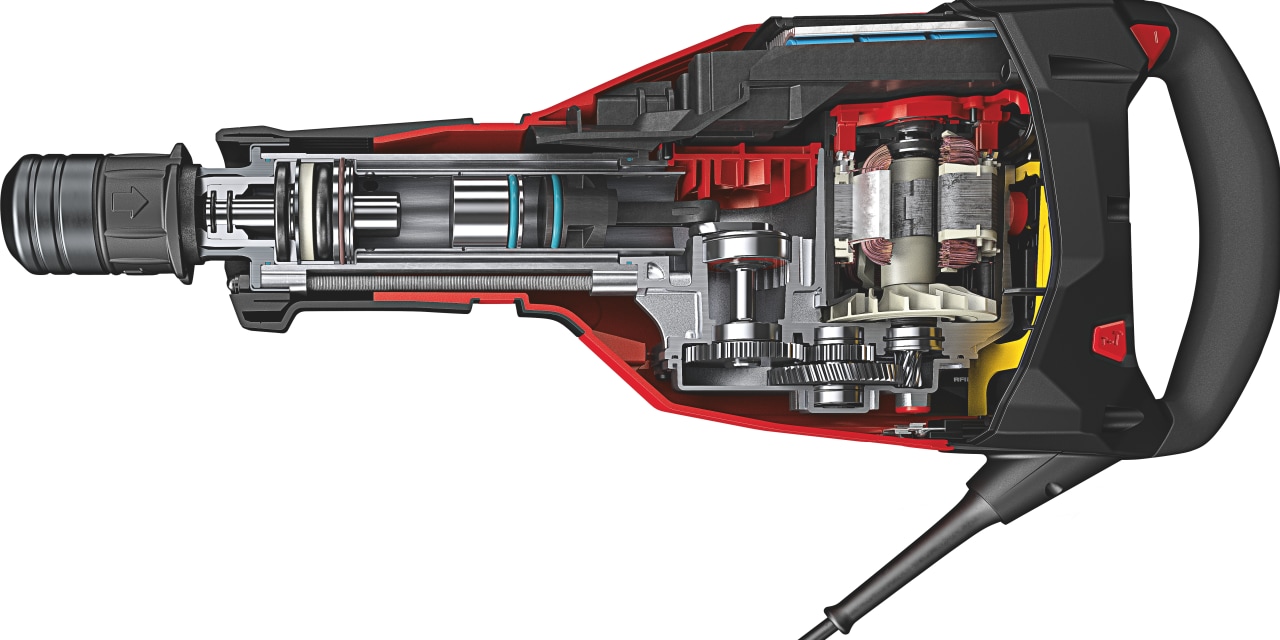

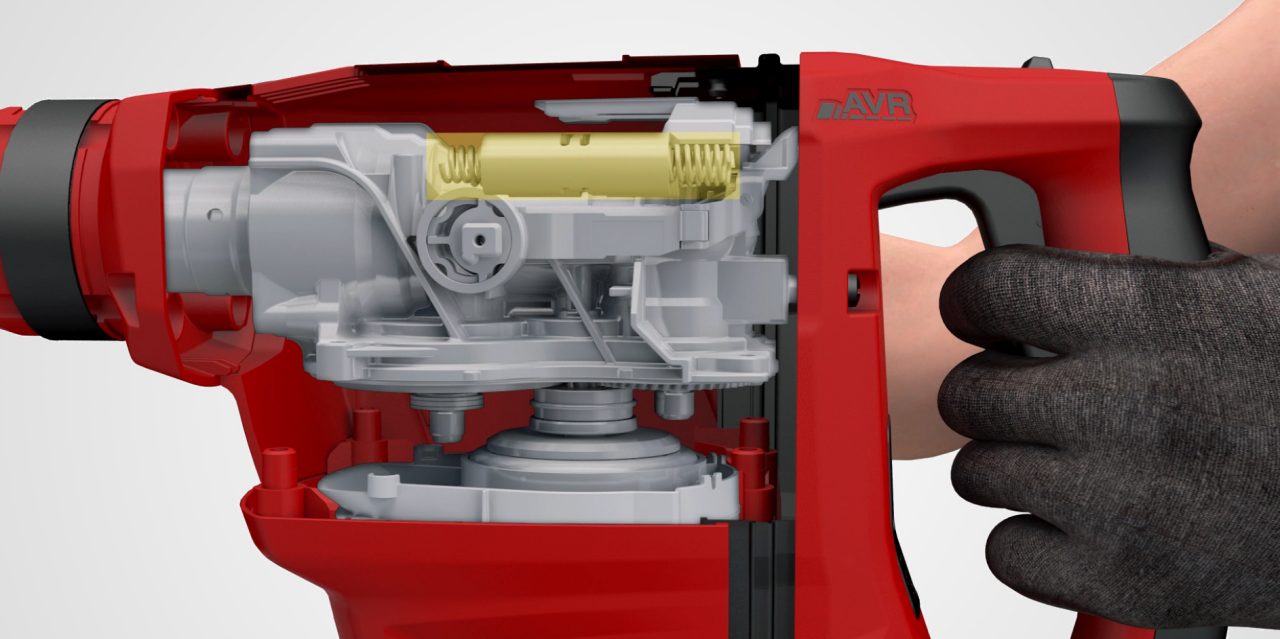

Through many decades of research and development, Hilti has been minimising power tool vibration using Active Vibration Reduction (AVR) systems. This technology reduces vibration by up to two-thirds compared to conventional tools, allowing them to be used for longer and more comfortably.

Choosing tools with AVR can significantly reduce vibration without compromising performance, making it easier to keep construction workers comfortable and productive.

Hilti AVR works in a number of ways to reduce power tool vibration to a minimum, including:

Sub-chassis systems

This technology features in tools such as the TE 1000-AVR breaker, where the motor is isolated from the external housing through a suspension system, absorbing vibration that would otherwise pass directly to the user.

Watch the video to see how the technology works

Vibration absorbers

Counterweights oscillate to counteract vibration in combihammers such as the TE 50-AVR, reducing the vibration which reaches the operator's hands.

Decoupled handles

Separating the vibrating section of the tool from the user with a built-in vibration absorber helps to reduce the worker's exposure to vibration. This technology is featured in our combihammers such as the TE 60-ATC-AVR.

Organisational: measures to reduce vibration exposure

The third stage of the “STOP principle” is to implement organisational measures that cut construction workers’ exposure to vibration to a minimum.

One way you can do this is to create a system of job rotation, making sure that construction workers switch between tasks that involve vibrating tools and others that don’t.

In the same way that you can use quicker, more effective tools to help reduce vibration exposure time, you can also combine them with quality inserts. High performance inserts don’t directly reduce construction vibration but they do help to get the job done faster, reducing trigger time, and therefore overall vibration exposure.

Good examples of consumable upgrades you can make include:

- Drilling: use ultimate TE-CX (SDS plus) hammer drill bits – with 4 carbide cutting edges – to get the job done faster

- Chiselling: opt for self-sharpening TE-SPX chisels which stick less, thanks to their polygon wave design

- Grinding: using SPX diamond cup wheels for faster grinding thanks to the dense concentration of high-quality diamonds, and lower vibration thanks to advanced core balancing technology

Your organisation should also provide team members with industry training to help minimise vibration exposure and recognise symptoms such as tingling or numbness. To help you with this, impartial advice and guidance is available from the HSE vibration web pages [3].

Need help identifying opportunities to minimise risk onsite and support with training your team on safe working practices? Why not speak to one of our expert Account Managers who offer guidance, advice and practical tool box talks onsite.

Personal protective equipment

Lastly, if there is no alternative than to expose construction workers to vibration, then it’s essential that they use relevant personal protective equipment (PPE).

Dust masks, eye protection, hard hats, ear protection, disposable overalls and gloves are all essential kit. Premium safety gloves have the added benefit of helping to keep hands warm and support comfortable working. It’s also important that tradespeople are trained not to push too hard when using tools, to let the tool do the work. That way, they reduce the power tool vibration they are exposed to.