- Home

- Solutions

- Solutions

- Firestopping and Fire protection

- Firestop in Sandwich Panels

Firestop in sandwich panels

Speed up your project with our certified solutions

Obtaining approval for firestop in sandwich panels can be frustrating, time-consuming and expensive. To help streamline the certification process and get your project off the ground quickly, Hilti has joined forces with two major European manufacturers to certify cost-efficient sandwich panel design solutions for a wide range of applications. Work with Hilti to get expert advice and support throughout the design and approval process, helping save you time, money and stress caused by delays and costly rework.

Benefits of sandwich panels

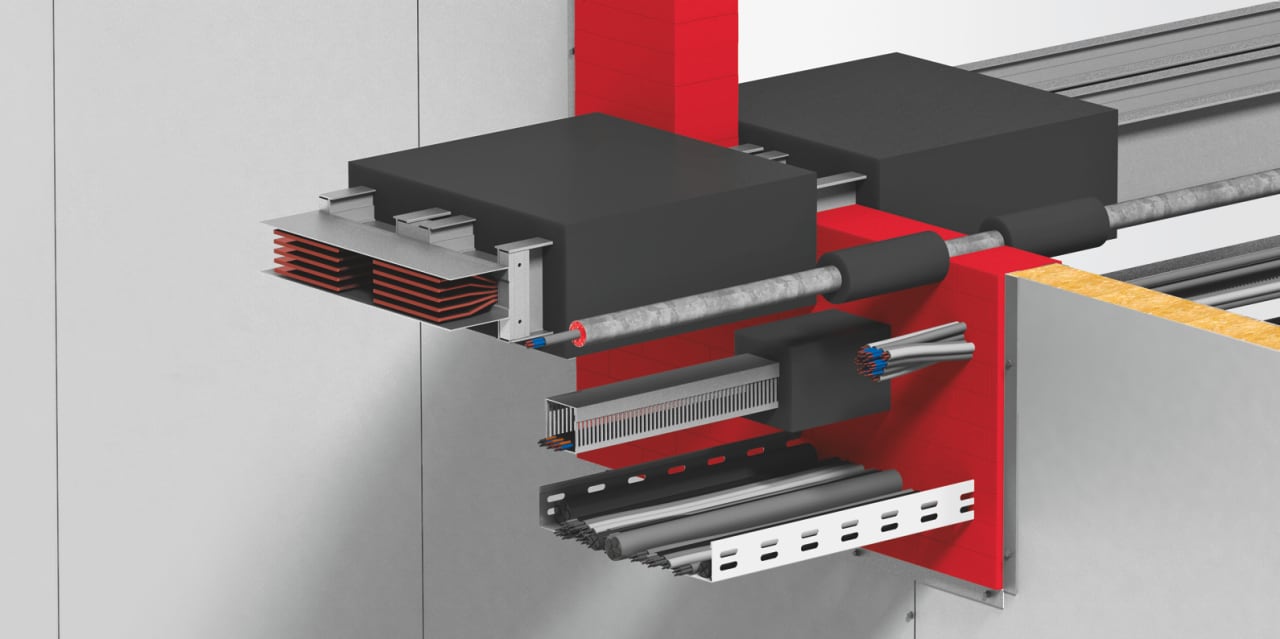

The use of sandwich panel wall systems can speed up construction cycles for large commercial and industrial projects. The light, prefabricated panels can be easily transported and quickly erected on site, allowing other trades to begin work immediately. In facilities such as data centers where every additional day of uptime counts, these fast-track construction methods can help improve and accelerate return on construction investment. However, while sandwich panels with mineral wool cores exhibit excellent performance during wall-certification fire testing, adding building service penetrations greatly impacts their fire performance and requires separate test certifications.

Passive Fire Protection

Lack of standardized testing for sandwich panels

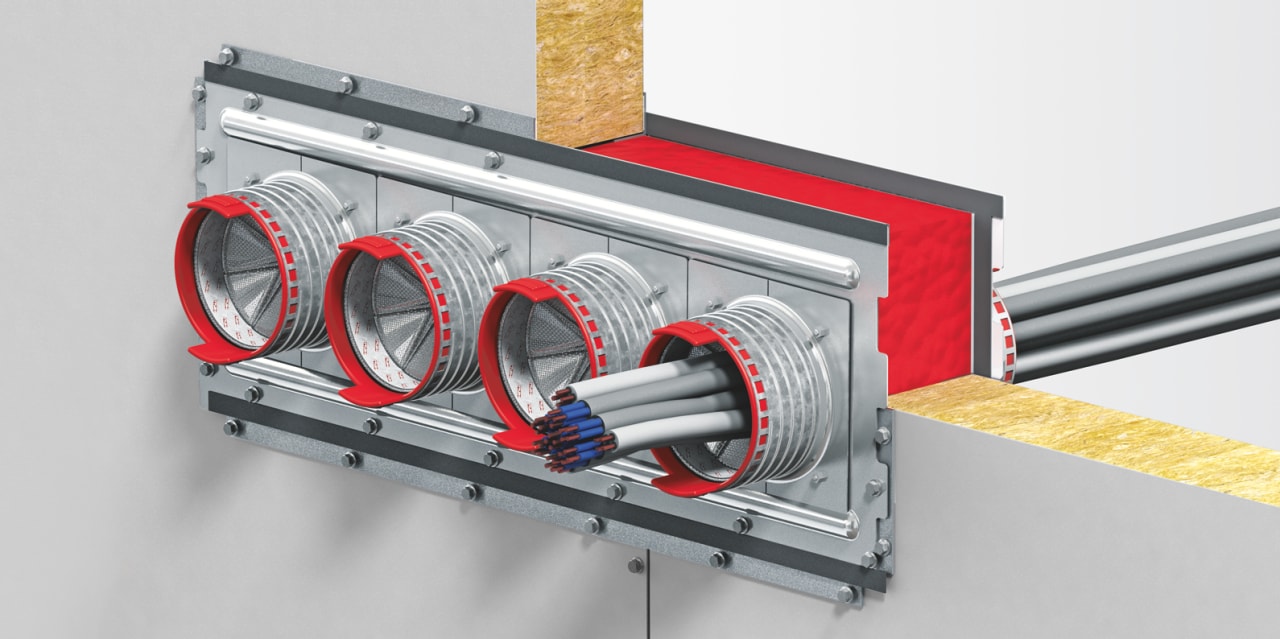

Fire tests of sandwich panel penetrations have confirmed that these wall types perform quite differently than standard drywall or concrete wall constructions. Unfortunately, the absence of standardized test methods and the huge variety of panel systems on the market has led to an industry-wide lack of testing for these wall types. This lack of testing means owners, designers and contractors have struggled with extensive schedule delays due to time-consuming engineering judgments and strict approval processes with local authorities.

Cooperative testing

Benefit from cost-efficient design

To help make commissioning faster and more reliable, Hilti’s Firestop team has worked with Paroc Panel System and Rf-Technologies (fire dampers) to provide tested and certified solutions for a wide range of applications. Coordinating densely packed services within tight technical areas is always a challenge. However, by combining the engineering power of three leading manufacturers, we can consider the structural requirements of sandwich panels alongside the spacing limitations of these certified fire penetration solutions. For the most cost-efficient design, contact us early in the design process - especially for firestop and fire dampers: by considering the parameters of tested systems early, you can help reduce time-consuming engineering judgements as well as costly rework, construction delays or commissioning problems.

Tailored solutions

From data centers to pharma

Whether you’re trying to get a hyperscale data center built at rapid speed or looking for solutions to meet stringent cleanliness standards in pharmaceutical or food plants, we have the expertise to help you meet your goals. Take advantage of the combined knowledge of Hilti, Paroc Panel System and Rf-Technologies to find solutions for your most technically complex challenges.

Firestop solutions*

Telecom

Firestopping for low-voltage cables and cable bundles

CFS-SL GA firestop sleeve CFS-BL firestop block CFS-D firestop cable disc

Mechanical piping

Firestopping for hot/cold/process water, refrigerant, sprinkler, process cooling, waste and drainage piping

CP 670 firestop board CFS-C EL endless collar

Rf-T fire dampers

Firestopping for round, rectangular and battery dampers with Rf-T CR2 and Rf-T CU2 (not produced by Hilti)

*Please note product offering and naming may vary in different countries. Please check the Hilti website or ask a Hilti specialist for local products in your country.

Your project partners

How Hilti can support you

Hilti experts are available to consult and advise you during the design and construction phases, whether at your office, via video conference or on the jobsite. We’ve gathered invaluable experience to inform our design recommendations and have extensive test data available to help answer any questions from local authorities. In addition, our specialized project teams can help to reduce risk of rework and increase productivity during construction. Get in touch with us today.