- Home

- Business Optimisation

- News and Events

- Hilti Blog

Hilti Blog

Discover the latest blog posts from the team behind the scenes at Hilti

The cordless concrete grinder that went viral

Lack of power supply? Working on scaffolds? Tired of pulling cables? No problem: the DGH 130-22 is the ideal concrete grinder for your job.

Read more

Be more productive on the site

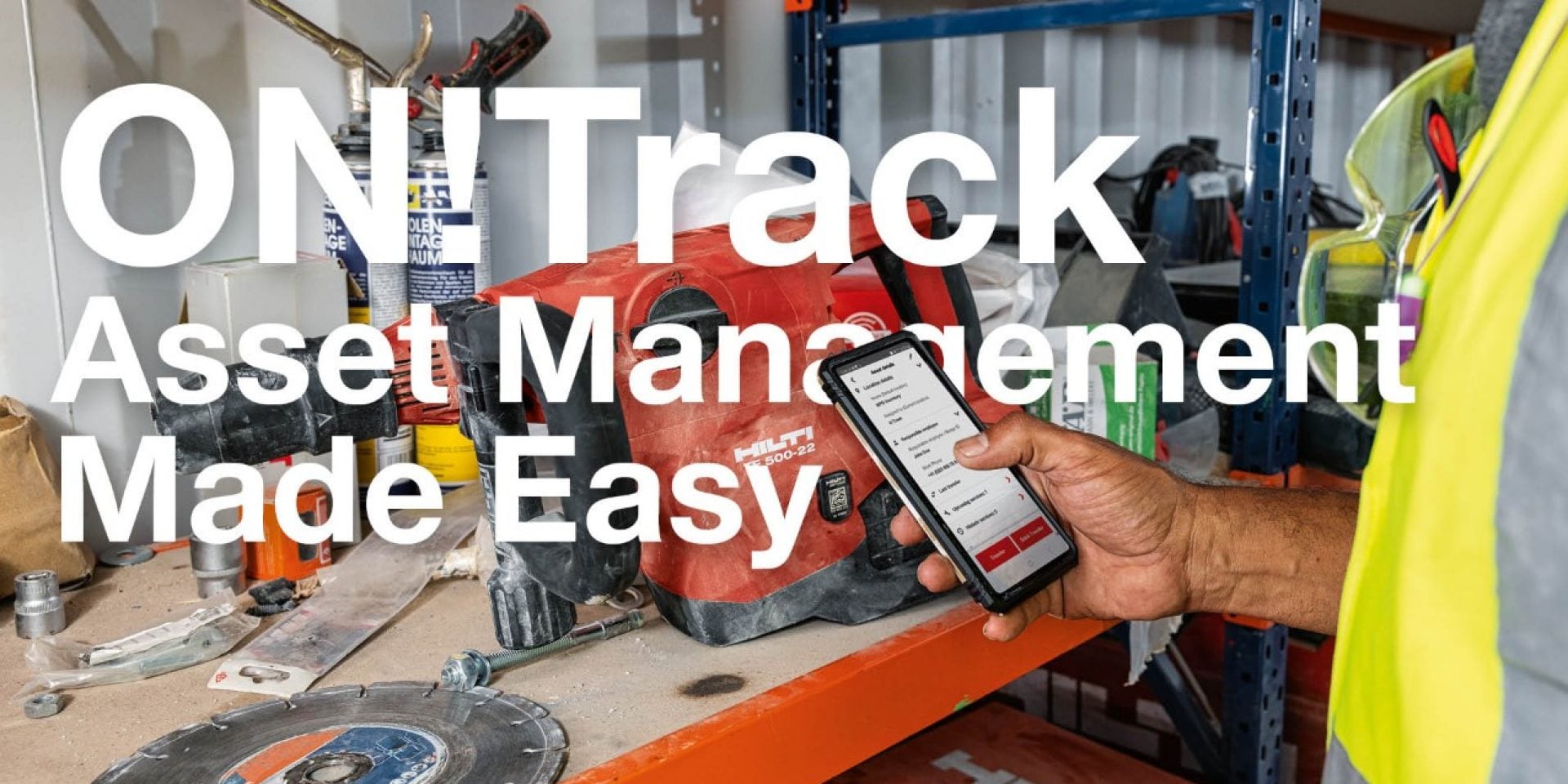

No matter what brand they are, you can track your tools, commodities, consumables, certification records and maintenance history at the click of a button with Hilti ON!Track.

Read more

How to improve cost control in construction

Hilti Fleet Management is a long-term tool hire solution where you pay a monthly fee for the tools you need across your projects.

Introducing New Online Repair Tracking

The full repair tracking process can now be managed via your Hilti Online account (24/7) meaning you’ll never have to pick up the phone.

Read morePRODUCTIVITY

Why purchase cordless power tools?

Not only does it save time, but it boasts added convenience to help you be more productive on site.

Read more

7 benefits to signing up for a Hilti online account

There's no better time to sign up for a Hilti online account. Find out why...

Read more

How automation can help tackle construction's biggest challenges

The robots are coming! But what role will they play in the future of construction...

Read moreSAFETY

Angle Grinder Safety

As one of the most popular tools on the jobsite, angle grinders can pose a risk when not used correctly.

Read more

How technology can help make the construction industry safer

Embracing technology has many benefits, including making your construction business safer.

Read more

Construction Dust FAQs

The most frequently asked questions about construction dust answered.

Read moreSUSTAINABILITY & FUTURE TRENDS

Sustainability in construction

At Hilti, we actively manage and take responsibility for the environmental, social and people impact of our activities through the implementation of sustainable business practices at all levels.

Read more

5 influencers to follow if you're obsessed with construction

From electricians to plumbers and carpenters, we've picked 6 of the most popular influencers from the UK that you'll definitely want to follow.

Read more

Answering the top 8 FAQs we get on social media

Ever wondered what our top FAQs are? We answer them in this blog!

Read morePress Enquiries

For all press enquiries and media requests